Precision Meets Innovation

Components for Industrial Applications and Creative Endeavors Alike. Serving Businesses and Makers Around the World.

Featured products

-

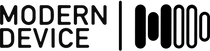

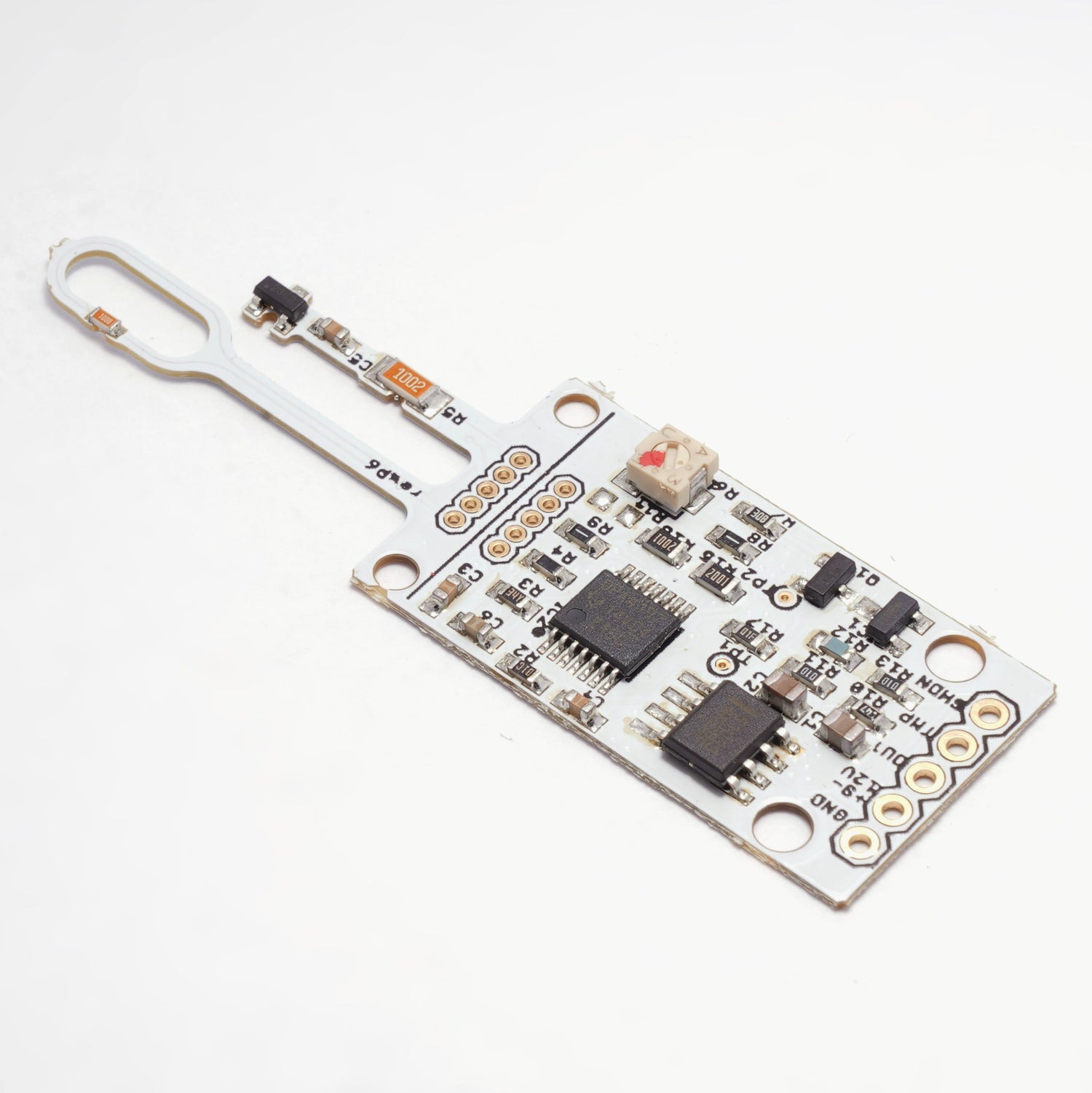

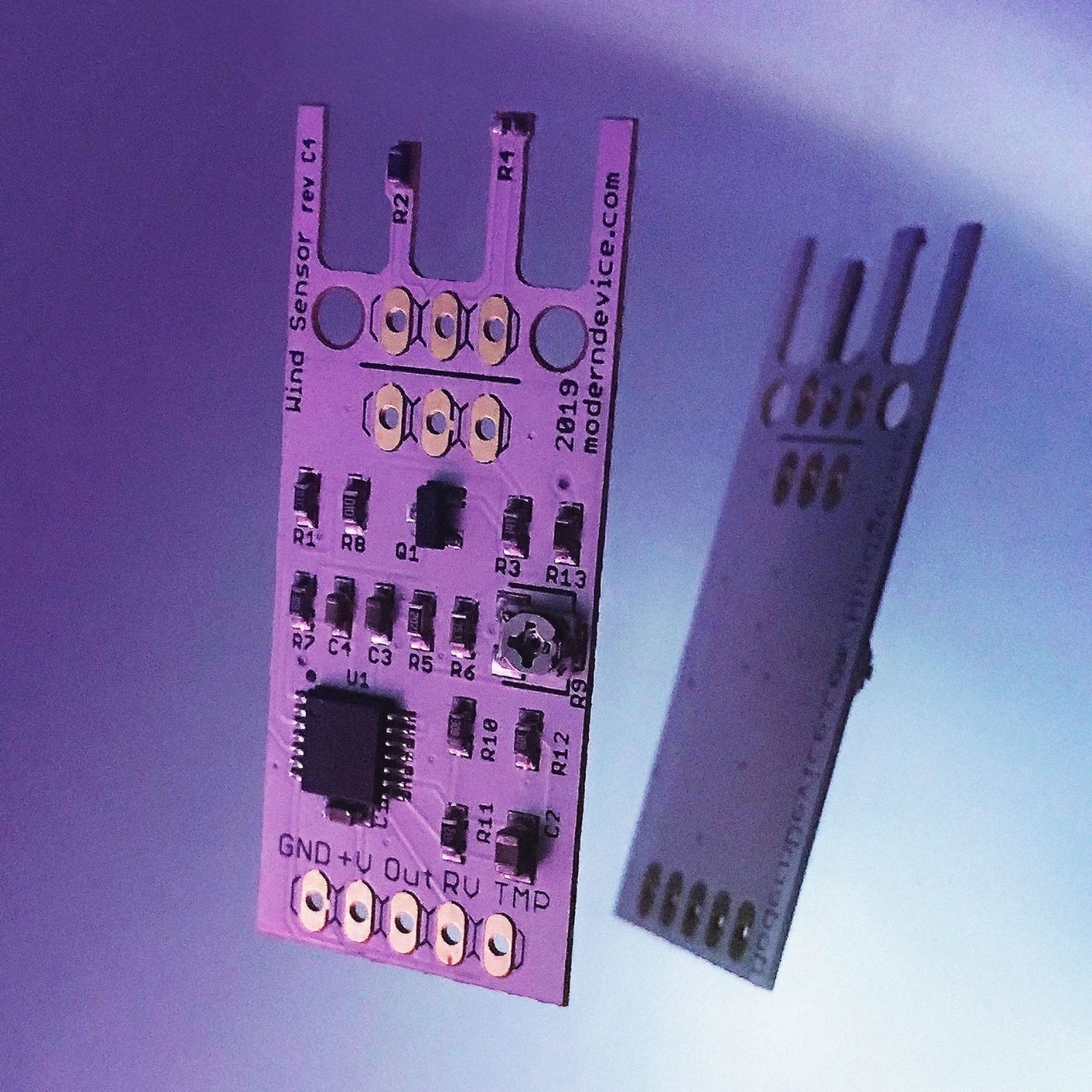

Wind Sensor Rev. C

Regular price $21.95Regular priceUnit price / per -

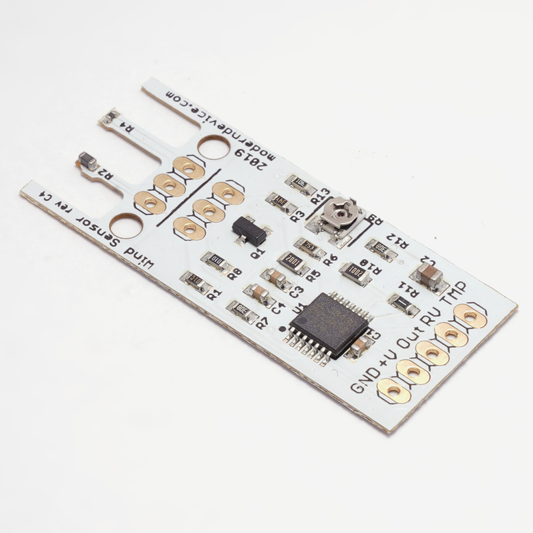

Wind Sensor Rev. P

Regular price $39.95Regular priceUnit price / per -

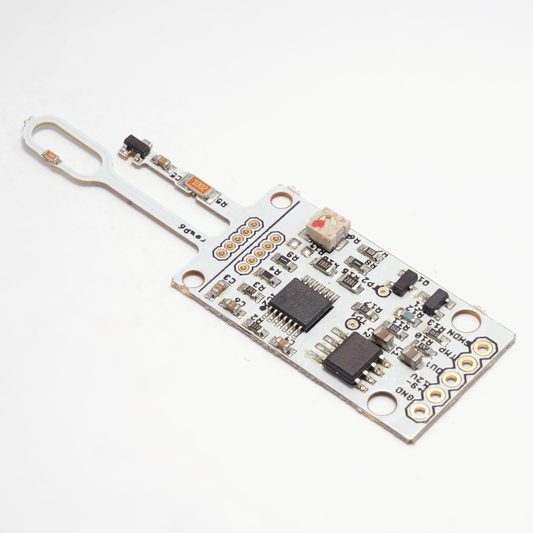

Reverbalizer: Hackable FV-1 Based Multi-effects Module

Regular price $59.95Regular priceUnit price / per -

Sold out

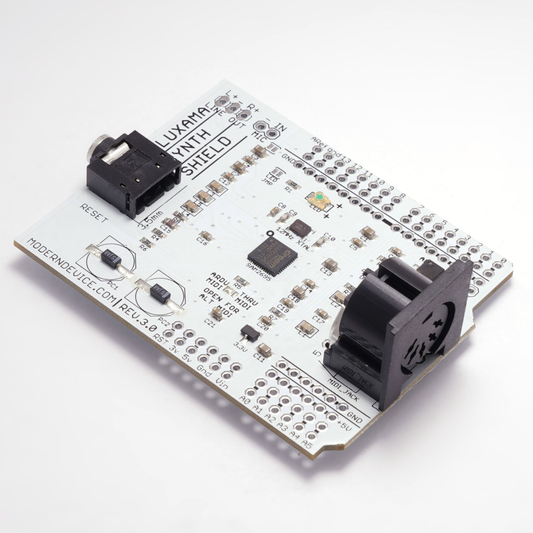

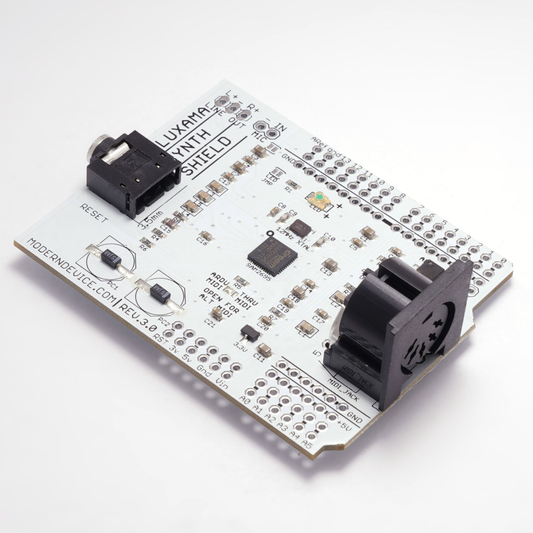

Sold outFluxamasynth Shield v.3

Regular price From $31.95Regular priceUnit price / per -

Sold out

Sold outAC Current Sensor

Regular price $19.95Regular priceUnit price / per -

Sold out

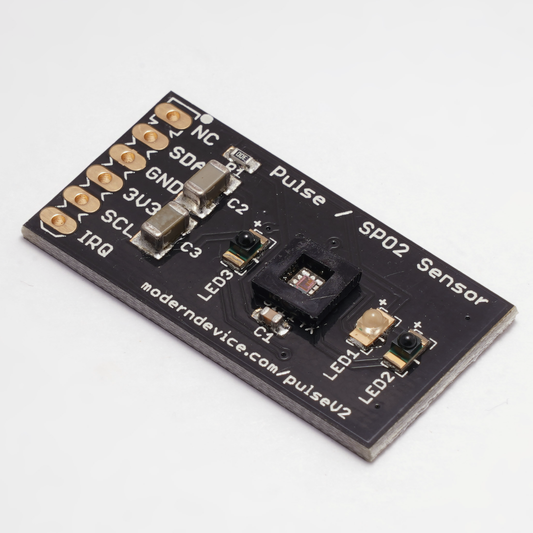

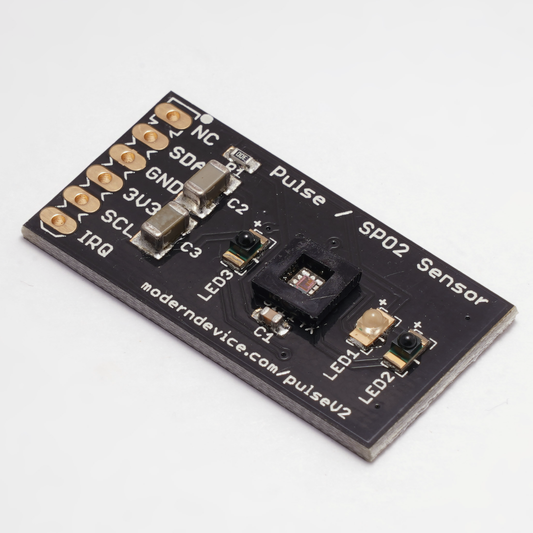

Sold outPulse/Heartbeat Sensor

Regular price $21.95Regular priceUnit price / per

1

/

of

6

Shop Collections

View all-

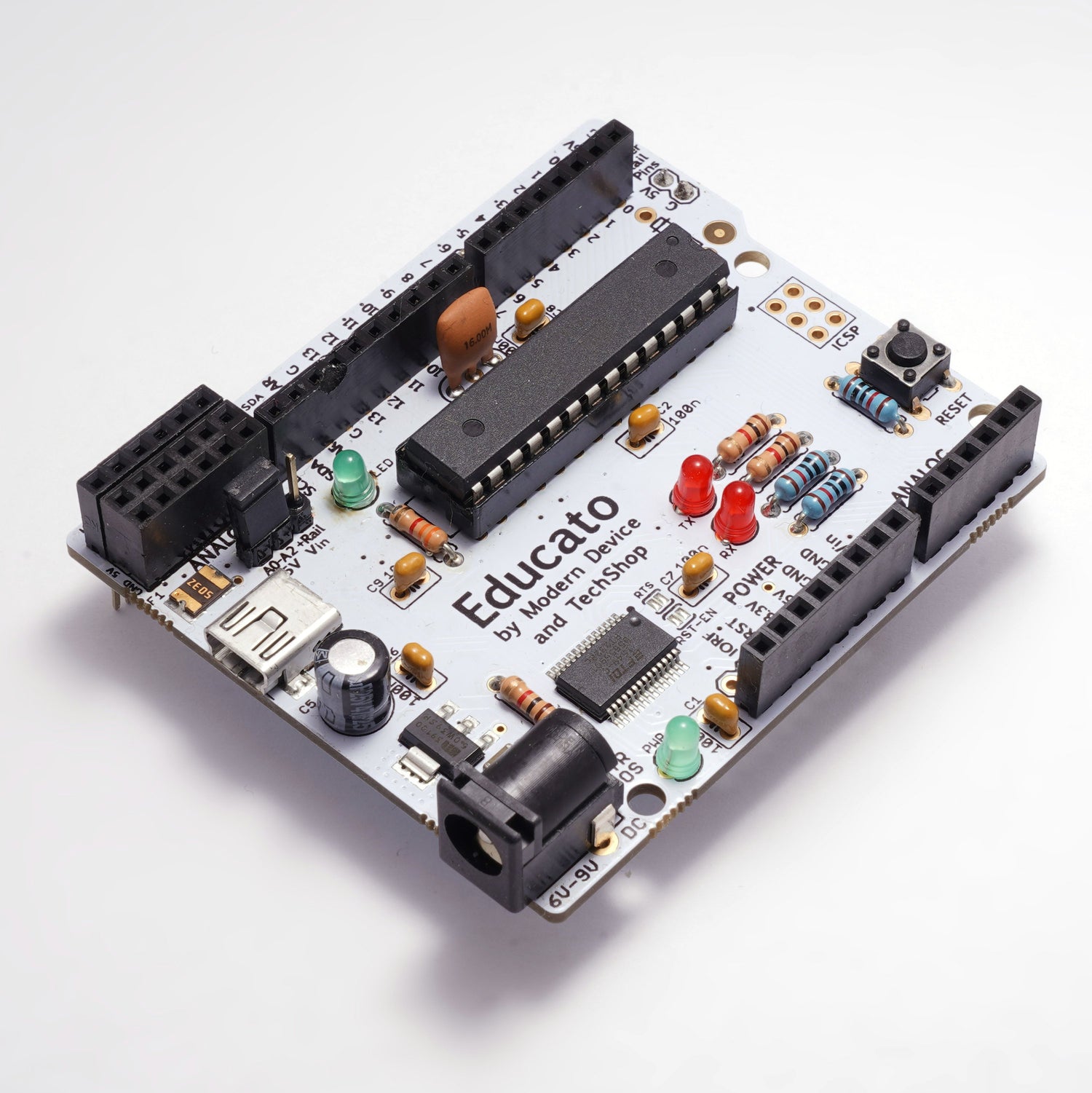

Synthesizers and Effects

Programmable synthesizers, sound generators, and effects, all in your control.

1

/

of

3